POSTED May 11th 2022

Why Ductile Iron Is The Dominate Material

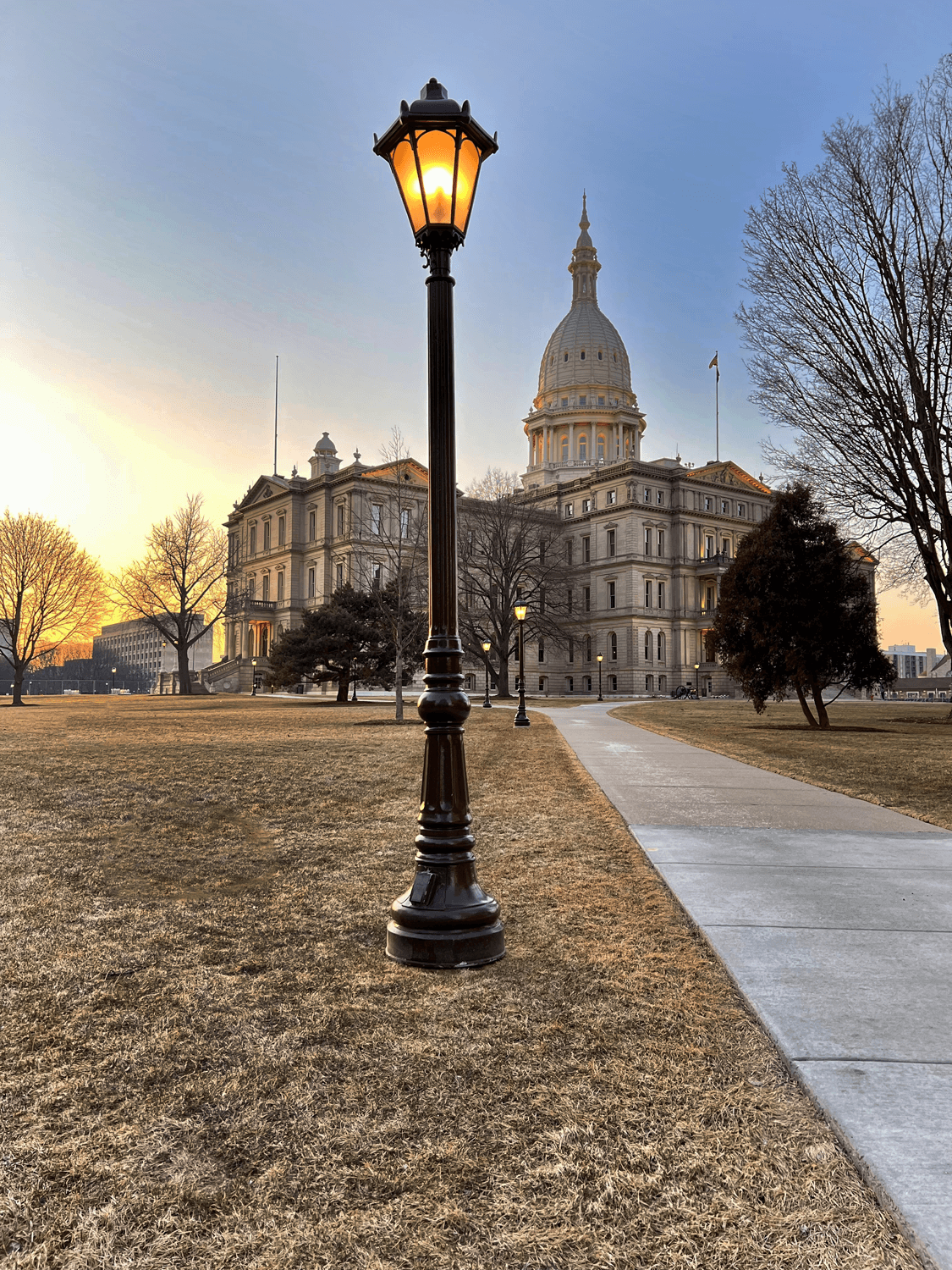

There are so many choices in decorative street posts. From the simple to the ornate, to custom or a stock design, it can be absolutely overwhelming at times. Not to mention what pole goes best with which luminaire. Among all these choices that make up the aesthetics of the streetscape the one option that many times gets overlooked is the importance of the pole material. Among those material choices, it’s safe to say that Ductile Iron is among the most advantageous for the majority of applications.

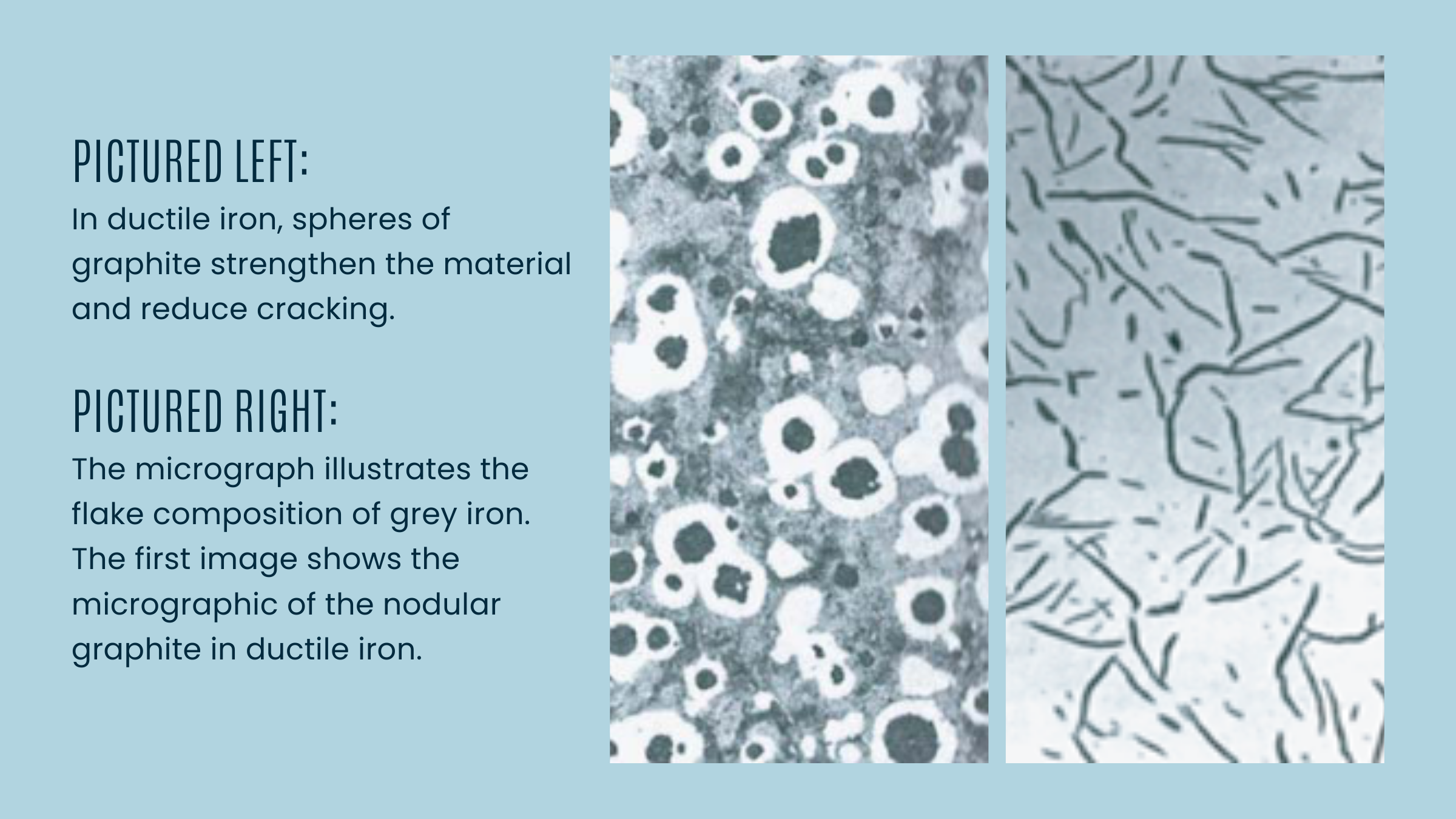

Ductile Iron was invented in the 1940’s by Keith Millis. While traditional cast iron uses graphite flakes and results in a more brittle finished casting, ductile iron is composed of spherical graphite and is made by treating molten iron with magnesium. The result is a cast iron that has much more impact and fatigue resistance, due to its nodular graphic inclusions. Since ductile iron’s commercialized introduction, it’s been used as a replacement in applications where strength must surpass that of aluminum.

Ductile iron produces a far superior light post for many reasons. From the design and manufacturing aspect, ductile iron has better castability and machinability. This equates to a material that can produce a more intricate design without sacrificing the economy of production. Beginning with the cast and through installation, it’s a far easier material to work with. For this reason, most of Spring City’s custom-designed light posts are manufactured utilizing ductile iron.

More important than the ease of manufacturing and installation are the benefits ductile iron provides in real world applications. Ductile iron light posts have a superior ROI when spread over the lifetime of ownership due to their performance characteristics. Ductile iron posts are much stronger than most other materials, resulting in superior wear resistance and are not easily damaged by impact. This drives the need for repair costs drastically down due to a variety of reasons, including collisions with automobiles, and not to mention the added safety to pedestrians against potential accidents. Combine that with the estimated 75-100 year life cycle of a ductile iron pole and it’s not difficult to see that the strength and longevity of the poles saves Spring City’s customers money in the long run.

Confucius once said, “The green reed which bends in the wind is stronger than the mighty oak which breaks in a storm.” Ductile iron received its name based upon the “ductility” characteristic it possesses. Ductility is directly related with damping characteristics. When those characteristics are applied to real world applications the end result is a light pole that is far superior for bridge installations as well in environments and scenarios with high wind. Ductile iron light posts are safer and will better endure harsh climatic environments. In fact the American Association of State Highway and Transportation Officials (AASHTO) acknowledged the bending strength of ductile iron to be 3-4 times that of cast aluminum and gray iron. If your project has significant load requirements, ductile iron will probably be the only material that will meet AASHTO wind loading requirements.

Every option has its place and every choice has its reason. Spring City manufactures poles utilizing a variety of different materials and combinations of materials. We work with our customers to not only help with the design, pole placement, necessary lighting standards, along with a variety of other details, but we will work with you to help specify the correct post material specific to your budget, environmental factors, and application. Give us a call for your next lighting project.